Advanced Solutions for Heat Transfer Equipment

APEX Group – a pioneer in high-quality heat transfer equipment design and production – boasts over 50+ years of invaluable experience. This extensive history underpins our leading-edge engineering, which is driven by patented technology. Our designs are compact, affordable, and ensure that operations adhere to the latest environmental regulations. Furthermore, they have an extensive lifetime due to advanced corrosion protection.

About us

Products

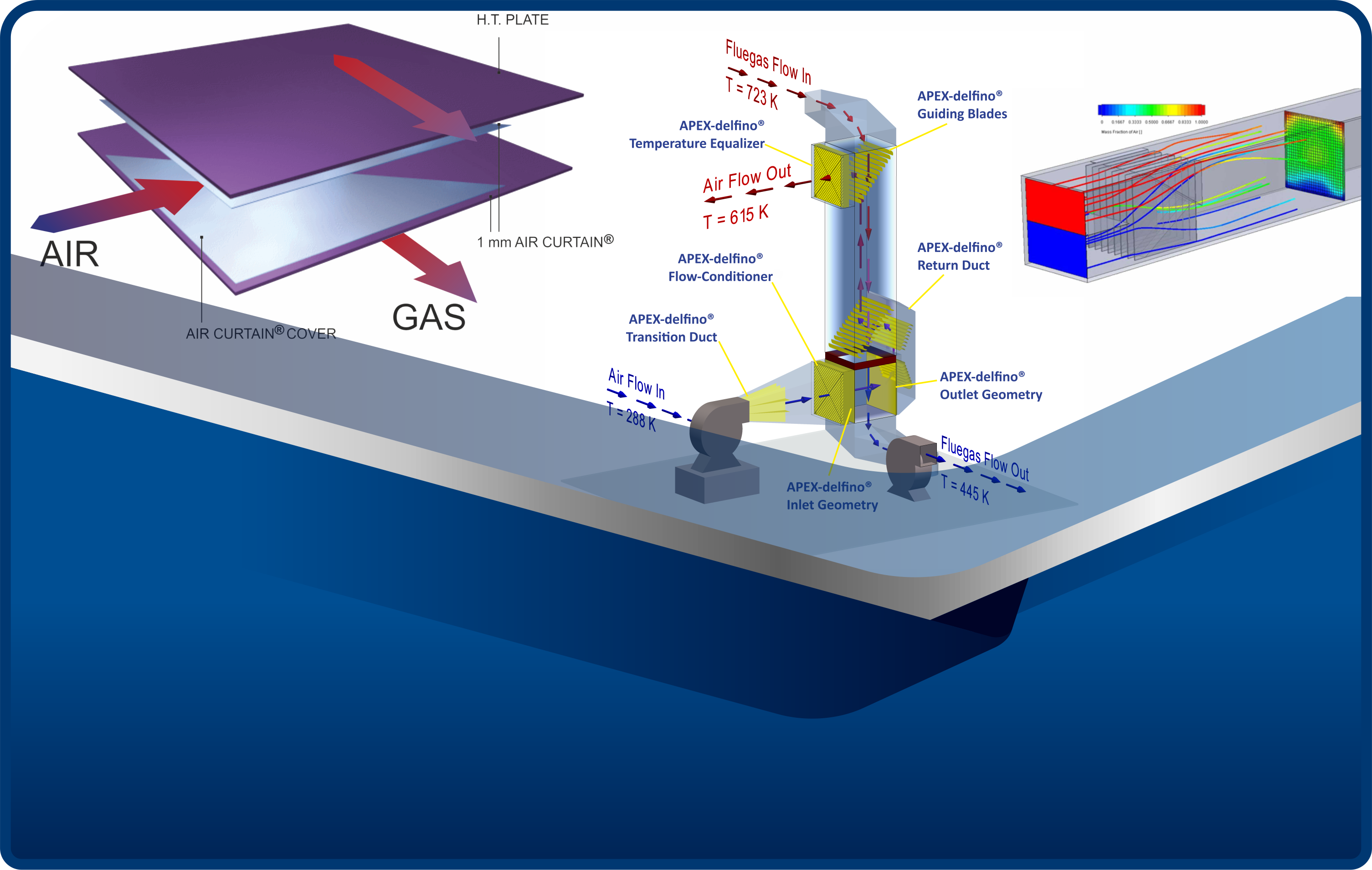

There are many economic and environmental benefits to installing a heat exchanger in energy-intensive processes involving fuel combustion. APEX Group products maximize these advantages because they are custom-designed according to our clients’ process and structural needs, and are supported by the latest innovative technologies developed by our in-house R&D department. Watch the video to learn more about our products.

Technologies

The green transition provides the impulse for energy-intensive industries to improve the efficiency of processes which require fuel combustion. One potential solution is to lower the stack temperature, reducing the total amount of greenhouse gas emissions. However, there is a major obstacle to implementing this solution: at temperatures below 150°C sulphuric acid condenses. This threatens the integrity of metallic heat exchangers as the acid has corrosive effects. Fortunately, through extensive research, our R&D team has developed heat exchangers which are suitable to work under corrosive conditions. These technologies present a cost-effective pathway for industry to abide by environmental regulations. Watch the video to find out more about our experimentation process and our corrosion-resistant heat exchangers.

In-House R&D

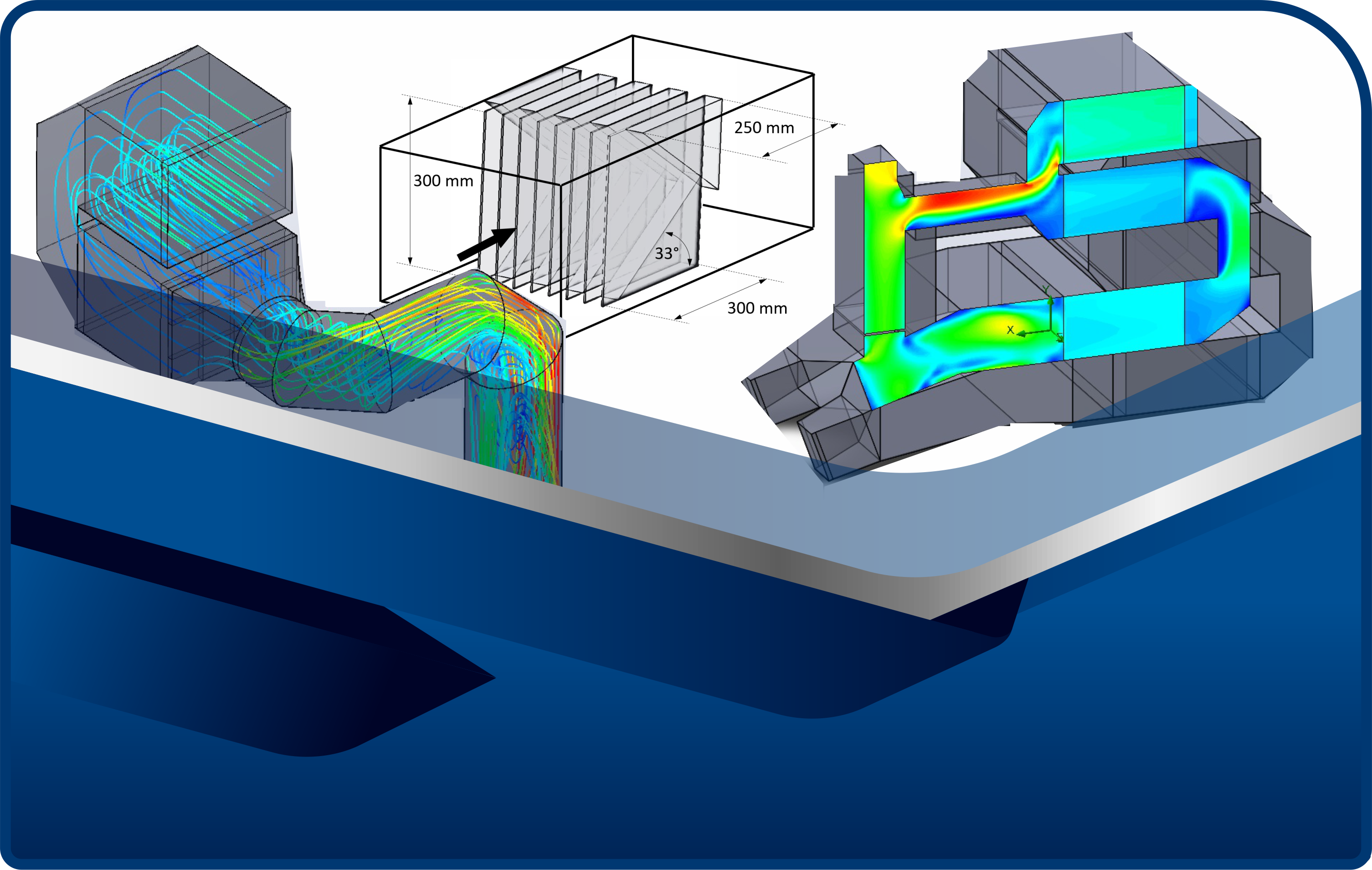

APEX Group’s in-house R&D Department is dedicated to broadening our knowledge of heat transfer, fluid mechanics and the properties of potential construction materials. The work of our R&D team enables us to continuously improve our products and deliver the best possible engineering solutions to our customers. Watch the video to find out more about what experiments are conducted and how our analyses are validated using cold flow modelling, Computational Fluid Dynamics (CFD) analysis and through the use of the latest laser optical measuring techniques that allow for air-flow visualization.

Key Numbers

After 30+ years of operations, we are proud of the following figures:

Deliveries

Testimonials

Orion S.A.

After spending over 6 unsuccessful months of CFD modeling to determine a satisfactory method of blending two fluegas streams at significantly different temperatures, we were running out of options. We contacted APEX for help and they offered their “Temperature Equalizer”. The Temperature Equalizer was installed in one of our North American Carbon Black plants and has proven to be a resounding success, mixing the two streams in extraordinary fashion. The APEX group solved the mixing issue with a very robust and effective design and we are very pleased with the results. – Orion-Americas Project Team - Orion SA

ENERGYNEST

Through its cooperation with APEX Group, ENERGYNEST can testify that this organization has an extensive expertise in the field of pressure vessel and steel structure fabrication. Their know-how and quality craftsmanship ensured that our six ThermalBatteryTM units – located at the Avery Dennison production plant in Turnhout, Belgium – were fabricated in accordance with the highest possible fit-up and welding quality standards. Having reliable partners such as APEX Group is crucial to our work; they enable us to guarantee that our product lives up to its state-of-the-art quality. Considering our long-standing relationship, we are happy to give them an enthusiastic endorsement. We believe that any organization requiring the fabrication of pressure vessels or steel structures would have their expectations met or even exceeded by APEX Group. This is in large part due to their extensive expertise and professional conduct.

Shell

During the preparation, design and manufacturing process, we have been able to experience the cooperation with APEX as pleasant and the complete package meets the requirements as stated in the scope of supply. - Shell Replacement Team

Stadtentwässerung Mannheim

Stadtentwässerung Mannheim would like to present our appreciation to APEX Group, regarding your professionalism in delivering the Heat Exchanger precisely fulfilling our expectation and plant’s demands. (…) Your high quality product keeps an outstanding performance for 10+ years, under the operation at high temperature (900o C) and in a very dirty environment. We would like to thank APEX Group for design engineering, fabrication expertise, excellent collaboration during project execution and after-sale service."