Quality Management System

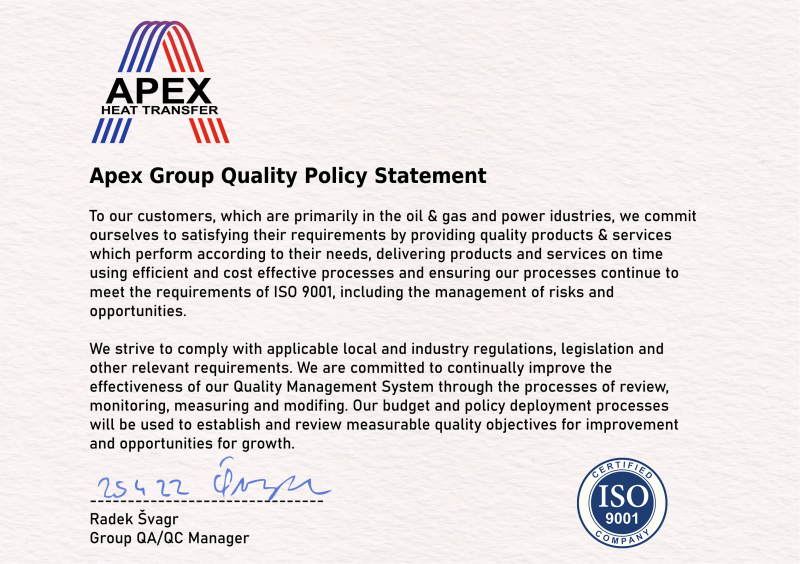

Since 1999, the APEX Group’s Quality Management System has complied with the requirements of consecutive generations of the ISO 9001 standard.

Certifications:

- EN ISO 9001

- EN ISO 3834-2

- EN ISO 1090-2 EXC3

- EN 12952

- EN 13445

- AD 2000 Merkblatt HP0

- ASME section I (S designator)

- ASME Section VIII Division 1 (U Designator)

- FROSIO