Company Profile

APEX Group’s guiding principle:

“Started in 1990 as a small independent business, APEX Group will grow into a reputable designer and manufacturer of high quality, low-priced industrial heat transfer and combustion equipment for the international market operating according to the quality principles laid out by international standard ISO 9001” (M. Dinulescu, 1991).

What can you expect from APEX Group?

High Quality Products

APEX Group heat transfer equipment is custom-designed according to our clients’ process and structural needs. Our propriety plate-type and tubular heat exchangers are suitable for a wide range of services, such as: combustion air preheaters, gas heaters or gas coolers.

Know-how and Innovation

APEX Group stands ahead of the competition because of its extensive know-how, patented technologies and leading-edge engineering. Our Research and Development department supports APEX Group’s activities by continuously upgrading our products. This guarantees efficient heat transfer, a long lifetime, and trouble-free, user-friendly operation.

A Highly Esteemed International Reputation

APEX Group has acquired a reliable reputation as a consequence of its many successful deliveries. We have serviced various reputable customers across the globe working in various sectors, such as: Oil & Gas, Energy, Petrochemicals, Waste-to-Energy and Environmental.

A Future-Oriented Outlook

APEX Group focuses on long-term sustainability and success. On the one hand, we strive to develop solutions and products that anticipate market needs by continuously taking onboard customer feedback. On the other hand, as a family-owned company, we are able to build close connections with our customers which ensures a personal approach and allows long-term professional relationships to form.

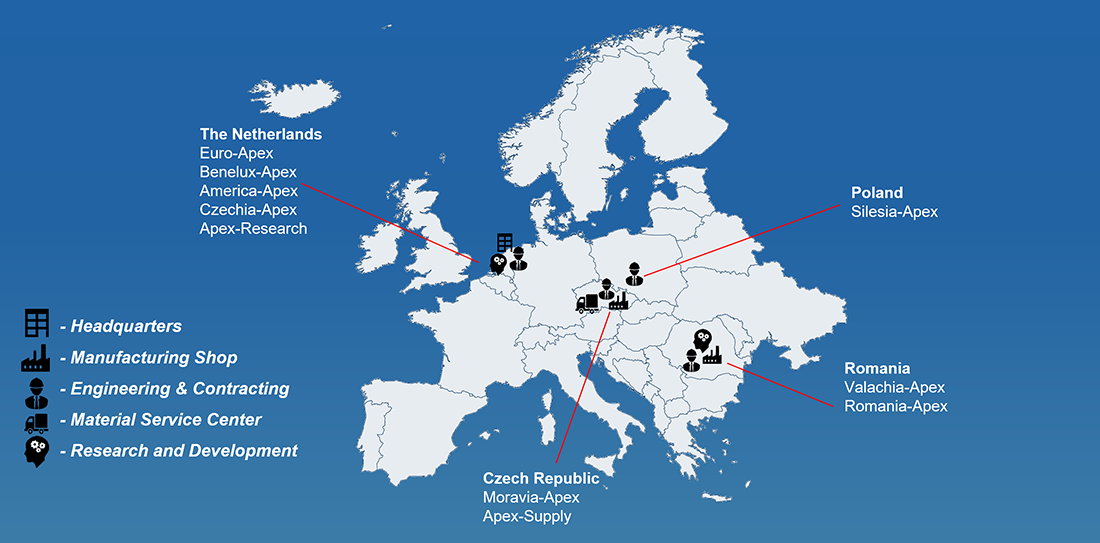

APEX Group Companies

Company Officials

Chief Executive Officer

Ms. Chris-Marije Dinulescu

+31 (0)70 300 4242

Contract Controller

Ms. Aleksandra Migas

+48 (0)32 381 5050

Technical Sales Managers

Mr. Bartek Migas

+48 (0)32 381 5050

Mr. Luis Fernandes

+31 (0)70 300 4242

Group Welding Engineer

Mr. Michal Kadlec

+42 (0)541 424 830

Chief Technology Officer

Mr. Artur Gajda

+31 (0)70 300 4242

In-house Legal Counsel

Ms. Iva Termorshuizen

+31 (0)70 300 4242

Project Controllers

Ms. Eleni Krul-Machaira

+31 (0)70 300 4242

Ms. Aleksandra Migas

+48 (0)32 381 5050

Mr. Ismail Ardahan

+31 (0)70 300 4242

R&D Manager

Dr. Jens Kitzhofer

+31 (0)70 300 4242

Group Finance Manager

Mr. Ben Noordhoek

+31 (0)70 300 4242

Mechanical Design Manager

Mr. Michal Roskošný

+42 (0)541 424 830

Logistics Manager

Mr. Mirek Krejsa

+31 (0)70 300 4242

Group QA/QC Manager

Mr. Radek Švagr

+42 (0)541 424 830