AIR-CURTAIN® Technology

APEX Group developed the AIR-CURTAIN® concept as an innovative technical solution for protecting the ‘cold-corner’ of heat exchangers. The use of the AIR-CURTAIN® technology in heat exchangers, which operate with a metal temperature close to the acid or water dew point, has proven to be effective and results in operation which is safe and eliminates the condensation of corrosive acid.

Controlling the Metal Temperature to Avoid Dew Point Condensation

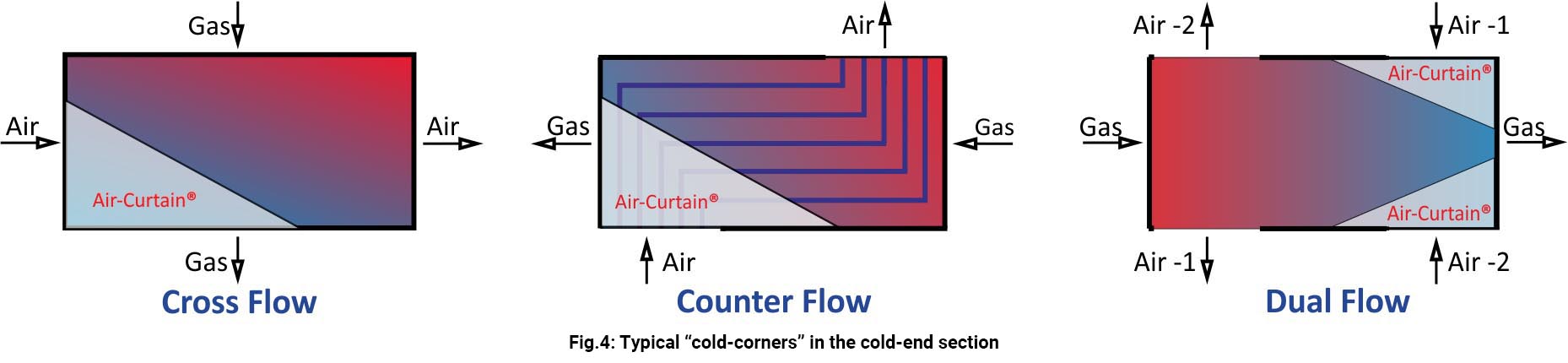

APEX Group AIR-CURTAIN® technology ensures that the metal temperature of the heat transfer surface in the ‘cold corner’ is kept above the acid or water dew point, eliminating the condensation of corrosive liquid. Most commonly this technology is used in air preheaters; the ‘cold corner’ in air preheaters is typically located at the cold air inlet and the flue gas outlet.

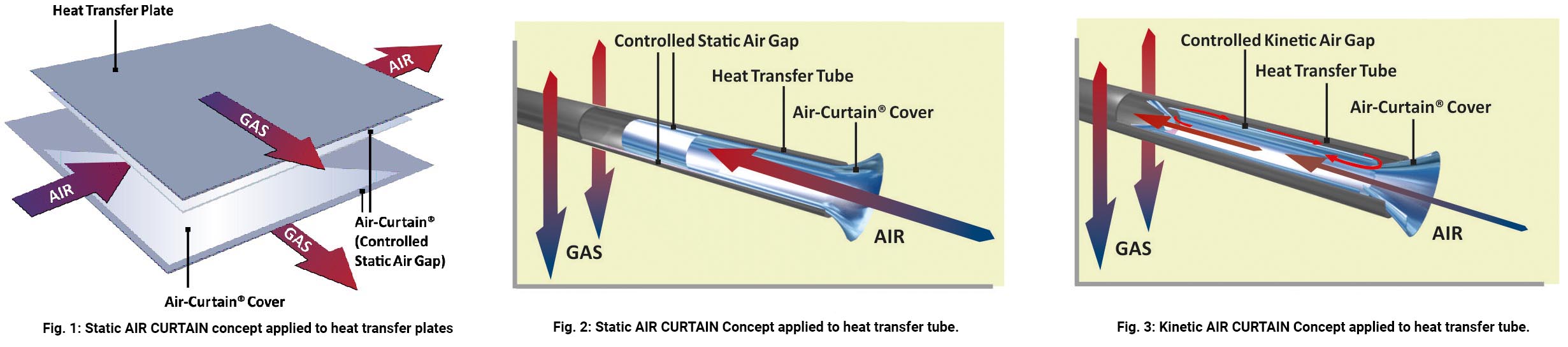

The AIR-CURTAIN® technology consists of a thin static (figure 1 and figure 2) or kinetic (figure 3) layer of air between the heat transfer surface and the heat sink stream. This layer acts as a part-insulator for the ‘cold-corner’ surface. On the one hand, the AIR-CURTAIN® increases the metal temperature. On the other hand, the heat sink stream performs the regular heat transfer function, with slightly reduced heat-flux. This lost heat-flux can be recovered in the sections of the heat exchanger operating fluids at higher temperatures, where condensation does occur.

The AIR-CURTAIN® technology is used at the ‘cold-corner’ of the cold-end section of the flue gas stream, as shown in figure 4.

The Risks of Dew Point Condensation

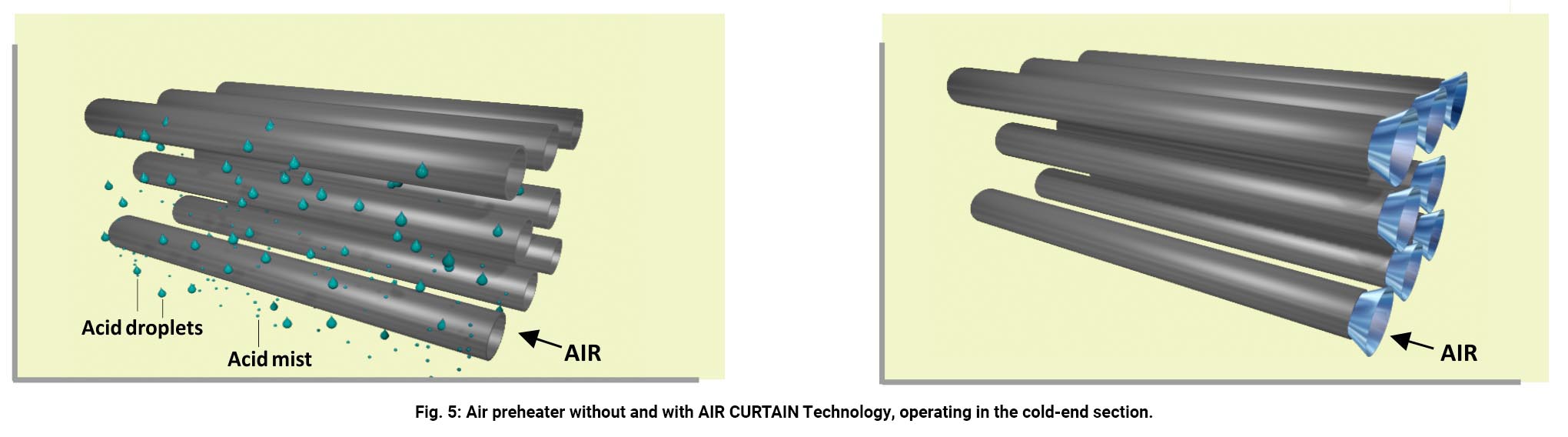

If an air preheater is without the protection afforded by AIR-CURTAIN® technology and is operating in the “cold-end” section of the flue gas stream, then it risks acid or water condensation onto the heat transfer surface. This liquid condensate is very corrosive and may damage the air preheater, the downstream equipment and the flue gas circulation system.

To remove this condensate, frequent shutdowns are required in order to clean the preheater. This has adverse environmental impacts, as the contaminated waters are discharged into sewers. Furthermore, shutting down an industrial operation is costly.

The AIR-CURTAIN® technology prevents acid or water condensation onto heat transfer surfaces and entrainment of the condensate droplets into the flue gas exhaust (figure 5). Therefore, it has a positive economic and environmental impact.

Key Benefits:

- Extends the lifetime of the air preheater by reducing or eliminating corrosion in the ‘cold-corner’;

- Reduces or eliminates fouling in the cold-end section and extends the maintenance-free operation period;

- Protects downstream equipment from exposure to the acidic condensate liquid entrained within the flue gas stream; and

- Reduces contamination of the cleaning water used to wash the air preheater during maintenance which is discharged to the sewer afterwards.