APEX-delfino® Temperature Equalizer

The following is typical for all heat exchangers: at the outlet of the streams there is a non-uniform temperature profile. This is problematic, because it affects the performance of equipment which is downstream from the heat exchanger. Fortunately, this problem can be overcome using the APEX-delfino® Temperature Equalizer. This device can also be used to mix 2 or 3 streams of gases at different mass flow rates, temperature and chemical compositions into one homogeneous stream.

Background: Temperature of the Stream at the Outlet of the Heat Exchanger - Design vs Reality

Typically, during the design of downstream equipment an important theoretical assumption is taken for granted: it is assumed that the temperature of the process streams leaving the heat exchanger is uniform.

However, in reality this is often not the case; the temperature of the stream leaving the heat exchanger is not uniform (this is true for virtually any type of gas-to-gas heat exchanger). In some instances, this can have negative impacts on proper operation of some downstream equipment, such as: ID fans, burners, SCR catalysts, bag filters, etc.

To solve this issue, our engineers at APEX-Research have developed the APEX-delfino® Temperature Equalizer which reduces the temperature gradient spread. This static device is tailor-designed to ‘equalize’, as much as is possible, the temperature gradient in a very short distance while ensuring a minimal additional pressure drop.

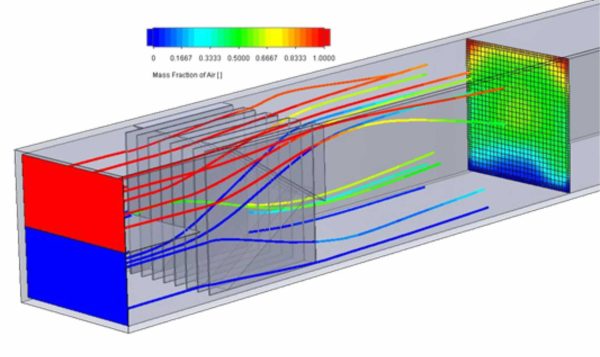

Figure 1 presents a computational fluid dynamics (CFD) simulation demonstrating how the APEX-delfino® Temperature Equalizer functions. The cut-plot – in which the mass fraction is color coded – demonstrates how the two streams are effectively mixed together after passing through the device.

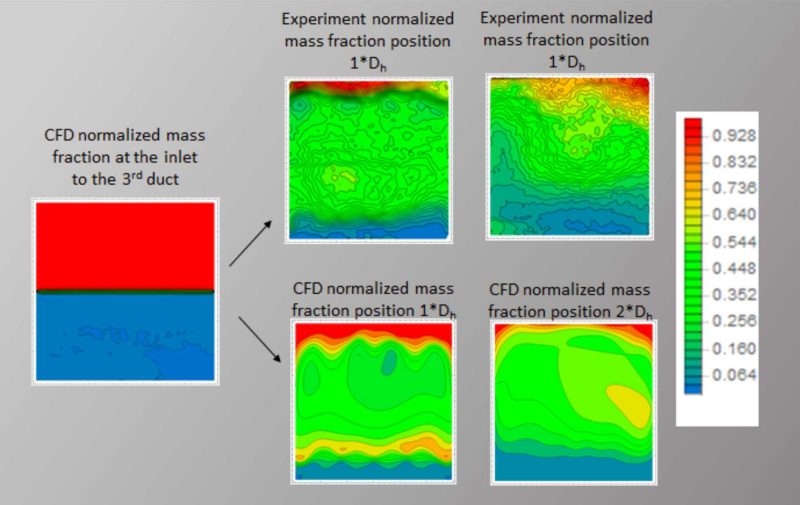

Figure 2 presents the results of a CFD simulation and an experiment in our laboratory. It is important to note the qualitative similarities of these results, measured at a distance of 1 and 2 hydraulic diameters downstream from the outlet of the APEX-delfino® Temperature Equalizer. We have used the results of many flow experiments to validate our method and to define the CFD boundary conditions used in our simulations. Once more, these results validate the effective mixing of both streams.

Figure 1. CFD simulation of the APEX-delfino® Temperature Equalizer – principle of functioning.

Figure 2. CFD simulation results (bottom) compared with laser optical measurements taken in the flow experiment (top).

Study Case: Mixing of several streams with different flow rates, temperatures and chemical compositions

The APEX-delfino® Temperature Equalizer can be successfully used to mix two or more streams with different flow rates, temperatures and chemical compositions, into one homogeneous stream.

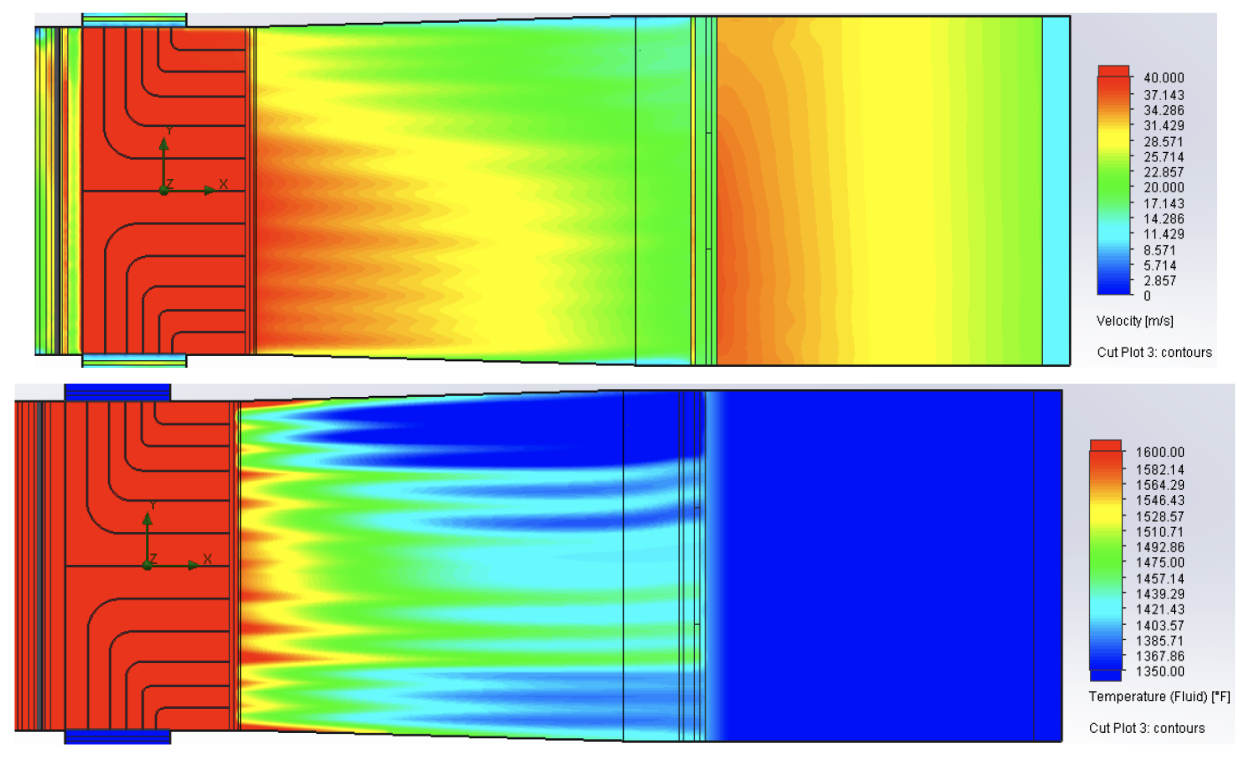

Figure 3 presents CFD simulation of APEX-delfino® Temperature Equalizer which mixes 3 streams of fluids.

The aim of this application is to cool the flue gas before it enters process equipment downstream and deNOx SCR catalyst. The flue gas is entering the device from the left with a temperature of 1010 °C and flow rate of 170,000 kg/hr. The cooling gas is entering the device from the top and the bottom in two streams with temperature of 320 °C and flow rate of 58,000 kg/hr, each.

The CFD simulation shows results of mixing the streams in terms of velocity and temperature. The outlet temperature gradient which is required by the design is achieved in a very short distance, equaling the temperatures in less than 2 lengths of the device itself.

Figure 3. Results of the CFD simulation; velocity profile of the mixed stream (top) and temperature profile of the mixed stream (bottom).