C-PEX® Coil Pressurized Heat Exchangers

APEX Group offers a range of tubular heat exchangers, either of proprietary or conventional design. These products can be used for heat recovery units or for a diversity of fired and non-fired installations.

Heat Exchangers for High Pressure Applications

C-PEX® heat exchangers are constructed out of bundles of tubes or pipes which are cylindrical, bare or finned in shape. The process fluid inside the bundle is pressurized (gaseous, liquid or multi-phase), while the fluid flow outside the bundle is non-pressurized.

The tubular heat exchangers may be supplied as stand-alone heat recovery units. They can also be supplied in combination with plate-type heat exchangers to form complex, integrated heat recovery units.

Key Features

Characteristics:

- ASME I, ASME VIII div. 1, EN 13445, AD 2000 certified

- Aluminum finning for clean fluids

- Steel welded or extruded finning for flue gases or industrial gases

- Variable finning density depending on allowable pressure drop, fluid properties (such as particulate matter content) and required cleanability

- Bare metallic tubes can be glass enameled and/or lined with polymer.

- Polymer tubes for highly corrosive applications

Fluids Handled:

- Air

- Flue Gas from combustion of: gaseous fuels, liquid fuels, coal, wood, waste, biomass

- Steam, water, glycol, oil

- Vapor (condensing or non-condensing)

- Process streams

- Industrial exhaust streams

Typical Services:

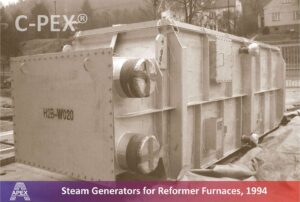

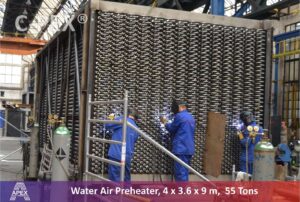

- Water or Steam Air Preheater (W/SAPH)

- Steam Gas Heater (SGH)

- Flue Gas Boiler / Boiler Feed Water Preheater (BFWPH) Flue Gas Economizer (ECO)

- Water/Flue Gas Cooler / Condenser (WGC)

Typical Technical Specifications:

- Design Temperature: Up to 900 °C

- Design Pressure: 150 barg

- Duty Range: Unlimited

- Thermal Effectiveness: Up to 70%

- Pressure Drop Rates: 0 to 0.1 barg (outside tube) or 0.5 barg (inside tube)

- Leakage Rates: Gas tight casing

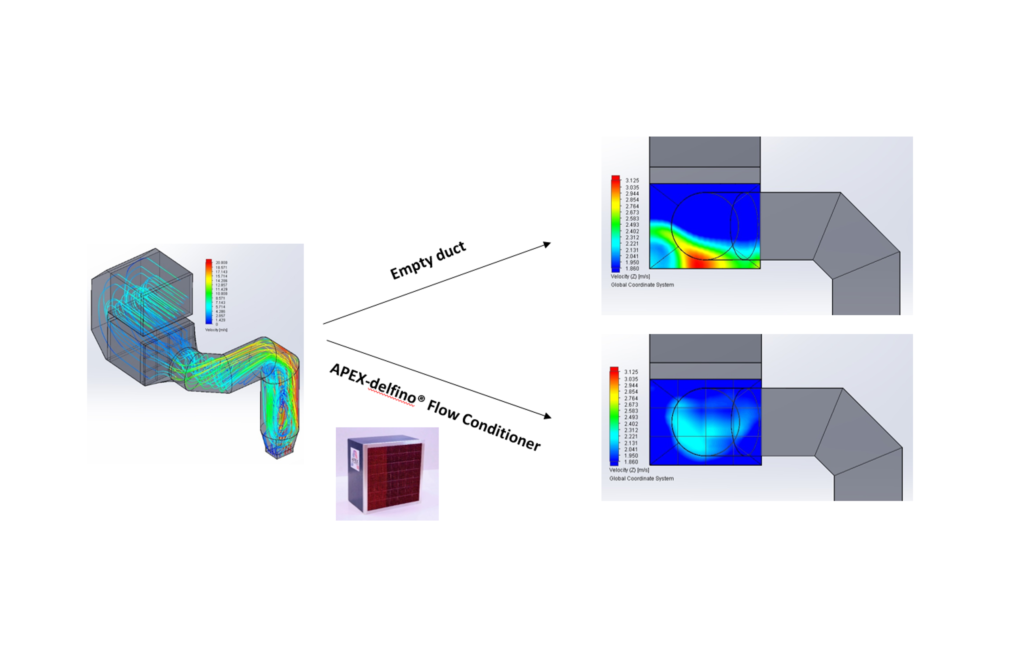

APEX-delfino® Technology

Applicable Technologies:

- A-CORREX® Technology – preventing acid dew point or water dew point corrosion.

- APEX-delfino® Technology – optimizing the fluid flow distribution and temperature profile.

Customized Solutions

Acid-resistant gas coolers

C-PEX® heat exchangers can be upgraded with A-CORREX® Technology. This changes the properties of the bare tubes as they become enameled, polymer lined, or made of polymer composite. Subsequently, the C-PEX® heat exchanger can be operated in corrosive environments (i.e., any operations which require flue gas to be cooled below the acid dew point).

Heat exchangers for heavy fouling applications

For applications with excessive fouling tendencies, heat exchangers can be constructed out of bare tubes. These bare tube products may be designed in combination with finned products to cover a wider range of process conditions within the same apparatus. Additionally, on-line water washing devices may be provided for moist and/or dust-laden gases operating at low temperatures.

Heat exchangers for clean-gas applications

Steel tubes with aluminum fins are suitable for handling clean gases, most commonly air. APEX Group offers a diversity of designs specially developed for applications such as air tempering and air preheating for combustion processes and for the process industry. The heating medium is steam, water/condensate, or water/glycol mixtures for environments which operate at freezing temperatures.

Heavy-duty heat exchangers

For heavy-duty applications, the tubular coils are made of steel tubes with welded steel fins. Such conventionally-designed units are used as convection section modules and gas-cooling modules for fired heaters, environmental projects, the process industry, etc.