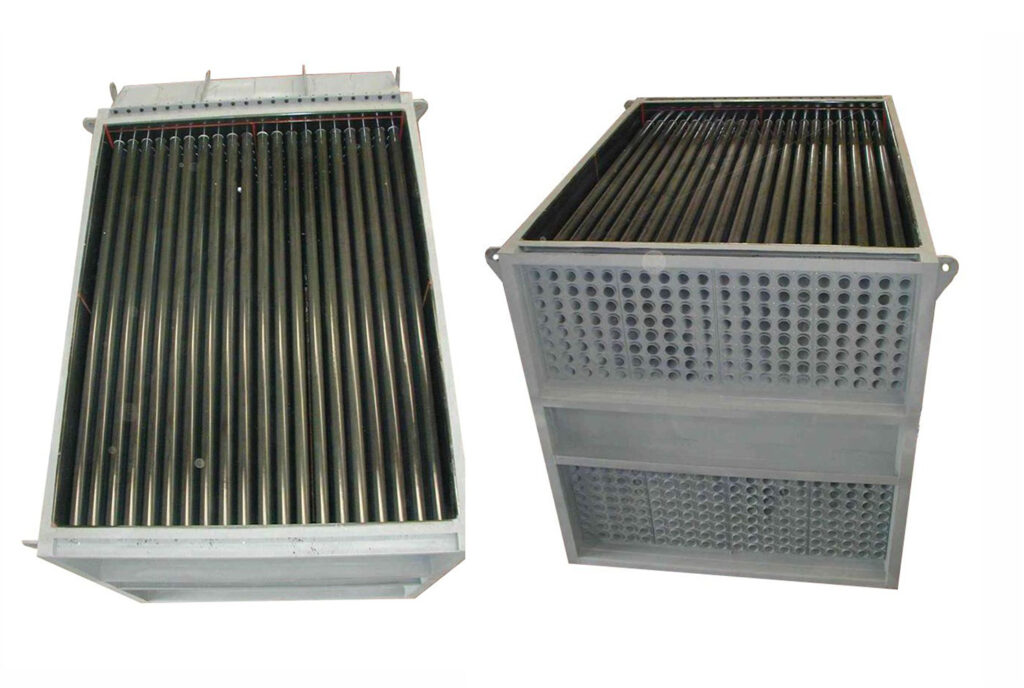

CORTEX® Core Tubular Heat Exchangers

APEX Group develops, fabricates and supplies a range of proprietary, non-pressurized tubular heat exchangers. The heat transfer elements are made of bare cylindrical or oval tubes and are arranged in triangular, square or rectangular patterns.

Heat Exchanger Operating in Corrosive Environments

Our CORTEX Heat Exchangers are upgraded with A-CORREX® Technology. This enables operations in which flue gas temperature can be dropped to below the acid dew point, further decreasing the exhaust flue gas temperature. This decreases operational costs and carbon emissions, and expands the possibilities for their use in emerging technologies, such as in carbon capture and storage (CCS).

Key Features

Characteristics:

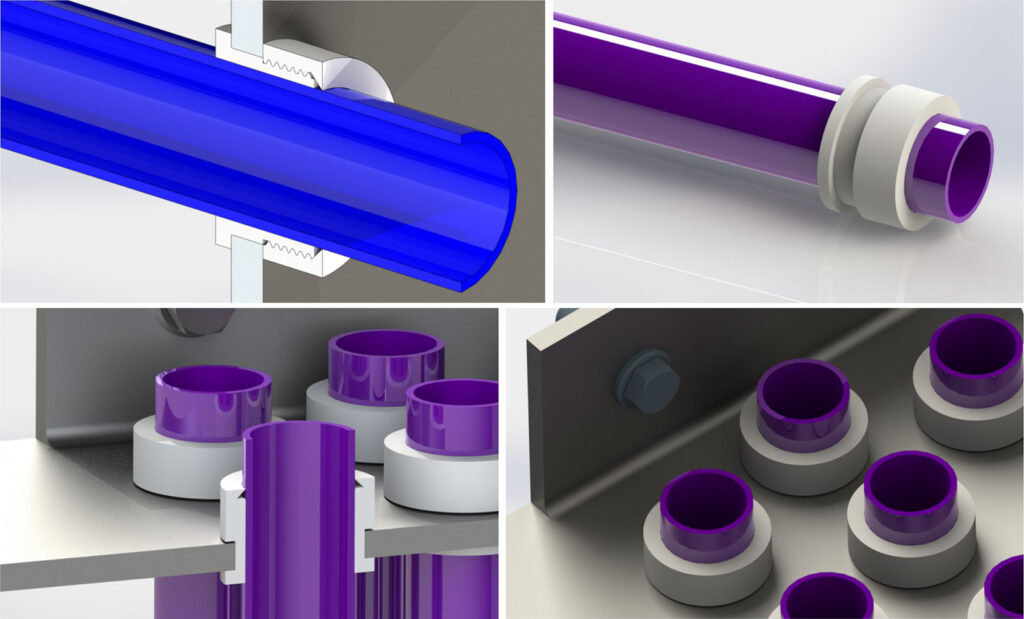

- Constructed from metallic (glass-enameled or polymer lined) or polymer composite tubes

- Suitable for working with corrosive (condensing) fluids (with A-CORREX® Technology)

- Easy replacement of the heat transfer elements

- Easy to wash due to smooth Glass enameled or polymeric surface

- Simple and cost effective construction

- Good response to thermal cycles and thermal shocks

- Relatively higher pressure drop and lower thermal effectiveness is achieved comparing to CORPEX® or V-FLEX® heat exchanger of the same size.

Fluids Handled:

- Combustion Air

- Flue gas from combustion of: gaseous fuels, liquid fuels, coal, wood, waste, biomass

- Vapor (condensing or non-condensing)

- Industrial exhaust streams

Typical Services:

- Combustion Air Preheater

- Gas-Gas Heater

- Flue Gas Cooler/ Condenser

Typical Technical Specifications:

- Design Temperature: Up to 260 °C (possible higher)

- Design Differential Pressure: Up to 0.5 barg

- Duty Range: Unlimited

- Thermal Effectiveness: ~70%

- Pressure Drop Rates: 0 to 0.1 barg (max. 0.5 barg)

- Leakage Rate: Less than 0.1%

A-CORREX® Technology

Applicable Technologies:

- AIR-CURTAIN® Technology – controls heat transfer surface temperature to avoid “cold corner” corrosion.

- A-CORREX® Technology – prevents acid dew point or water dew point corrosion.

Corrosion Resistant Materials

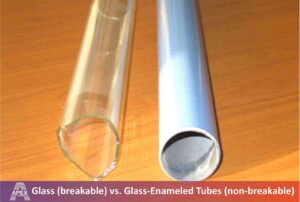

1. Glass-Enameled Steel

- Made from carbon/stainless steel enameled with borosilicate glass

- Resistant to Sulfuric Acid condensate from flue gases

- High thermal conductivity of carbon steel

- Extremely smooth, effectively repelling fouling and easily cleanable with water or steam

- Operating temperature up to 260°C (up to 450°C possible)

- Good resistance to heat cycles and thermal shocks

- Easily replaceable heat transfer elements (tubes)

- Mechanical strength of the metallic substrate

- Extremely smooth, effectively repelling fouling and easily cleanable with water or steam.

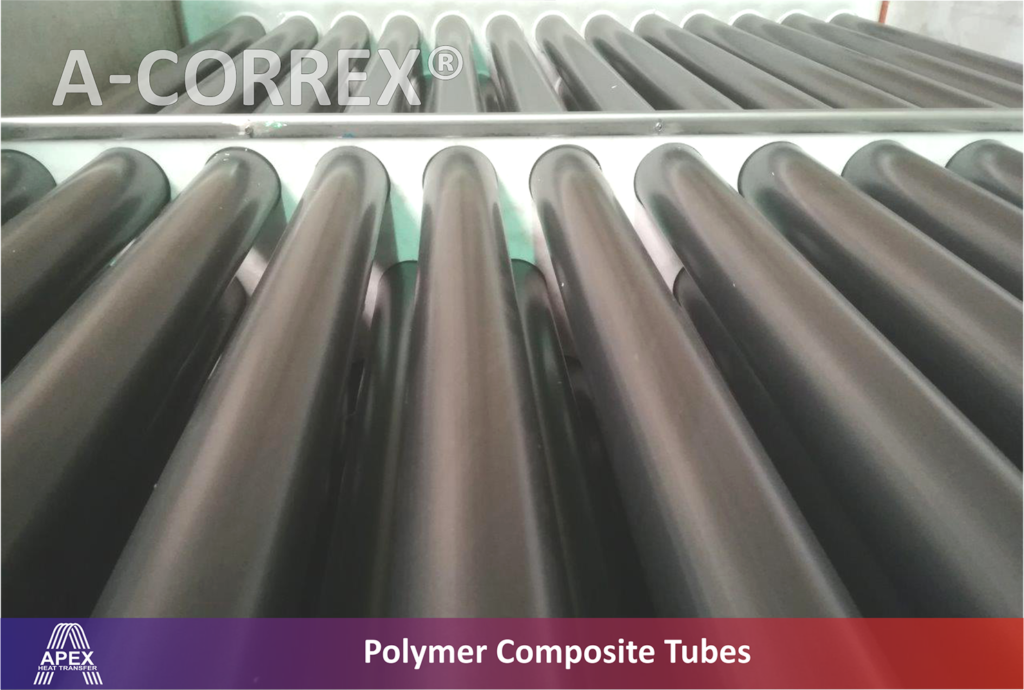

2. Polymer Composite

- Made from a special type of Polymer, featuring a higher thermal conductivity compared to pure polymers

- Resistant to virtually any chemical attack below Acid Dew Point and Water Dew Point

- Operating temperature up to 200 °C (short term peaks 220 °C)

- Good resistance to heat cycles

- Easy replaceable heat transfer elements (tubes)

- Light weight