APEX Group proudly announces the opening of a new build factory and offices in Czech Republic!

After 7 months of hard work, which is relatively short for this type of investment, we managed to finalise over 7,500 m2 of fabrication & administration building, in an overall premises of 30.000 m2.

The new construction provides premises for two of our companies: APEX-Supply, Material Service Center, and Moravia-Apex, Manufacturing Facility.

It is well established that APEX Group has two manufacturing facilities: Moravia-Apex in The Czech Republic, operating since 1992, and Valachia-Apex in Romania, operating since 2008. Valachia-Apex’ investment for a manufacturing facility was finalised in 2012.

After successful completion of the group’s first substantial investment challenge (Valachia-Apex’ new facility), we eagerly took upon ourselves a second sizable investment challenge. In 2019 we proceeded to build a new and modern facility equipped with state-of-the art technology for Moravia-Apex and Apex-Supply.

Due to its unique and modern design, this building has already won the award for 2019 Best Industrial Building of South Moravia Award.

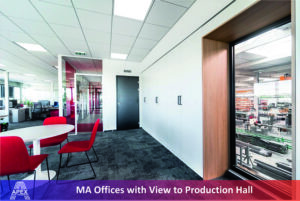

The facility includes modern offices, sanitary and canteen spaces for both Moravia-Apex and Apex-Supply. The space has been optimized for both the group’s material centre (2,600 m2 hall) and for manufacturing facility (4,400 m2), which includes a storage & trial assembly area of 600 m2. It additionally includes a tall hall of 1,300 m2, with a height under hook of 10.1 m, and a low hall of again 1,300 m2, with a height under hook of 6 m. This allows more flexibility in handling the units, making it easier to coordinate a wide scope of activities and to maximise efficiency.

APEX Group is proud to present a separate stainless steel production area and a separate stainless steel sandblasting booth, with glass granules.

The facility also has a sandblasting booth for carbon steel (steel grit) and a painting booth, both being equipped with heavy duty carriages, which assures airless painting and dying with temperatures up to 60oC and automatic drying systems.

Our CEO, Chris-Marije Dinulescu, is optimistic that this heavy investment in the group’s manufacturing facilities will solidify over the years a leading position as high quality manufacturer of APEX Heat Exchangers.